DOORCO Ltd Invest In A Turn-Key Schuberts Finishing System

@DOORCO Ltd is the UK’s leading innovator in the composite door industry with a reputation for building the highest quality doors to match the increasing industry demands. DOORCO also offers a wide range of door designs that enjoy success in both the commercial and retail sectors and is consistently bringing new products to the market.

DOORCO offer 3 levels of supply to their customers:-

Containers direct for large volume fabricators;

Stock orders from their UK warehouses, where they will supply anything from 1 door to mixed pallet volumes;

Prepped door blanks, offering customised door specifications on size/hardware/ and pre-finished, all completed in their modern UK facility and turned around in 4-7 days.

Renowned for introducing many composite door ‘firsts’, DOORCO is about to launch yet another new approach when it comes to colour. Thanks to its investment in partnership with Schuberts the market leader when it comes to paint drying and finishing, DOORCO is launching a new way of thinking to allow customers of all sizes to achieve the highest quality custom finishes in record time.

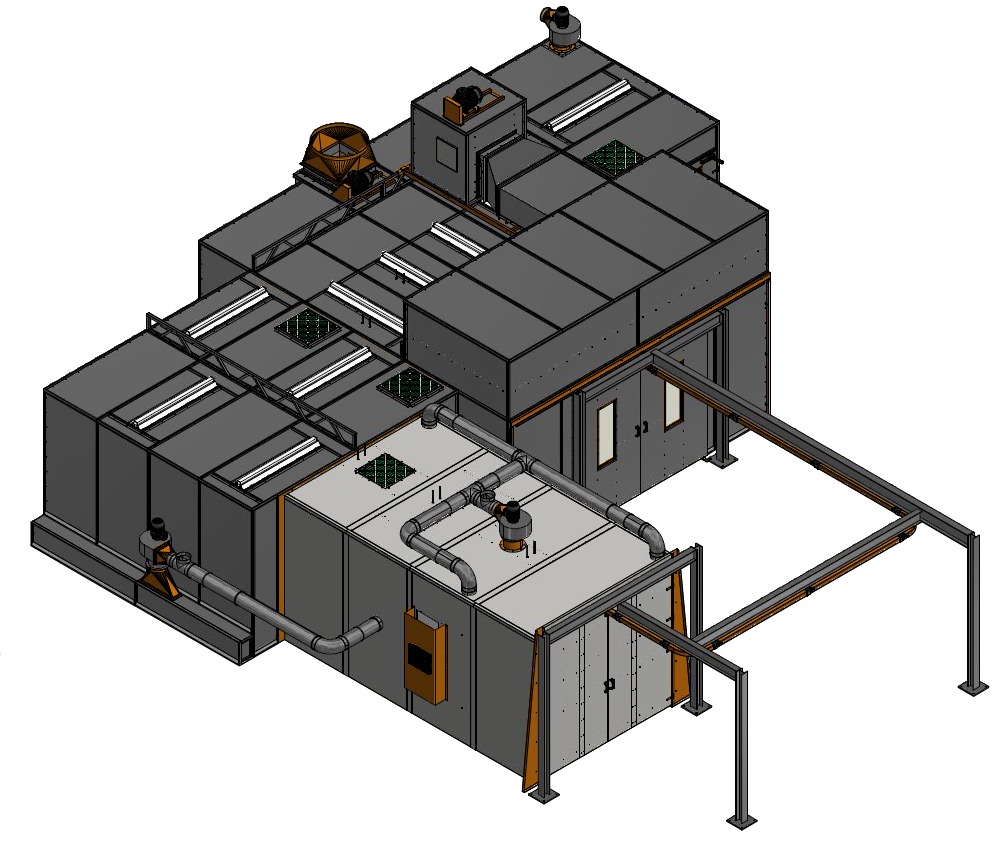

The investment process started months ago when DOORCO engaged with Schuberts to design a purpose-built flexible spray finishing system. Trials were carried out with their @RegaLead range of coatings at the Schubert Test Centre in Sheffield, where the full process was demonstrated on production-scale equipment. Doors and components are prepped, including being masked off and either etch wiped or rubbed down with special abrasive pads.

Once prepared, the doors are cleaned and either loaded onto the new overhead track or onto adjustable trolleys and moved into the spray enclosure. Here, they are sprayed in a controlled, clean environment. The air pressure is controlled so that no dust-laden air can enter and no vapours can escape. All the overspray is contained in Andreae double layer filter. Noise is kept to a minimum and airflow to a maximum by using fully ATEX rated centrifugal fan sets. These fan sets are inverter driven and controlled automatically by the spray enclosure control panel, meaning airflow rates are always kept to the correct level, up until the overspray filters are ready to be changed.

All the mixing and colour matching is carried out in a new purpose-built paint mix room. A bunded floor to collect spills, ATEX heating, permanent extraction, filtered air input and a custom workbench all mean it’s a safe and clean room to get those colours right, first time.

After coating, the 2k coated products are placed into a dedicated flash-off zone. This area is fed with filtered air input and low level extraction. The temperature is slightly above ambient to allow the coating to flow, vent and start to knit into the surface of the GRP composite door.

The key to the super-fast turnaround for DOORCO is the Schubox. This non-standard intrinsically safe Schubox drying system allows their full range of water based or solvent based coatings to be cured in a fraction of the time at the lowest of temperatures with the cleanest of processes.

The Schubox runs at just 35c and completely dries the products in 30-40 minutes before either returning back into the start of the process for a second colour or taken off the line and fitted up ready for shipping. The technology inside the Schubox has been specifically designed to work at low temperature and will not affect the substrate as hot air gas systems do. Long wave IR, air movement, reflection and an elevated temperature allow the Schubox to dry product in record-breaking time!

Matthew Le Masurier, DOORCO’s Senior Production Manager comments: “Colour represents 60% of DOORCO’s sales and the trend is relentless. With the demand for colour comes the demand for paint. That’s why we took the decision to invest in the Schubox® system which is universally accepted as the most advanced and efficient IR drying and curing system of its type in the world. It will help us to ensure we maintain control of supply and continue to meet the necessary lead times, regardless of colour. In a nutshell, the new finishing line means that doors will dry in 30 minutes compared with 3+ hours. This increases our capacity because as everyone knows, the main bottleneck in painting is the drying process. Schuberts have been fantastic to work with from start to finish and we look forward to passing on the benefits of this investment to our customers when production starts this month. “

“We feel the real-world value of all our recent operationally investments, including the Schubox is immeasurable. We understand the high value attached to customers’ peace of mind that their doors will be delivered on time, every time even when they’re coloured. Unlike some manufacturers with a simpler business model, automation for DOORCO is critical because we have such a diverse spread of customers, ranging from one-off prepped doors to containers. Each one is important to us. It’s thanks to the investment we’ve already made on behalf of the supply chain and are continuing to make, we can ensure we’ll continue to raise bar on our customer service and delivery on robust operational targets, whilst staying at the forefront of product quality and new innovation especially when it comes to colour.”

To learn more about DOORCO’s high quality offering for composite doors, contact info@door-co.com

If you want to explore custom made Schuberts finishing systems for GRP composites, contact sales@schuberts.co.uk

#DOORCO #finishing #composites #grp #schuberts #schubox

Leave a Reply

Want to join the discussion?Feel free to contribute!